Unlocking the Power of Angle Grinders: Tips, Tricks, and Top Uses for Every DIY Enthusiast

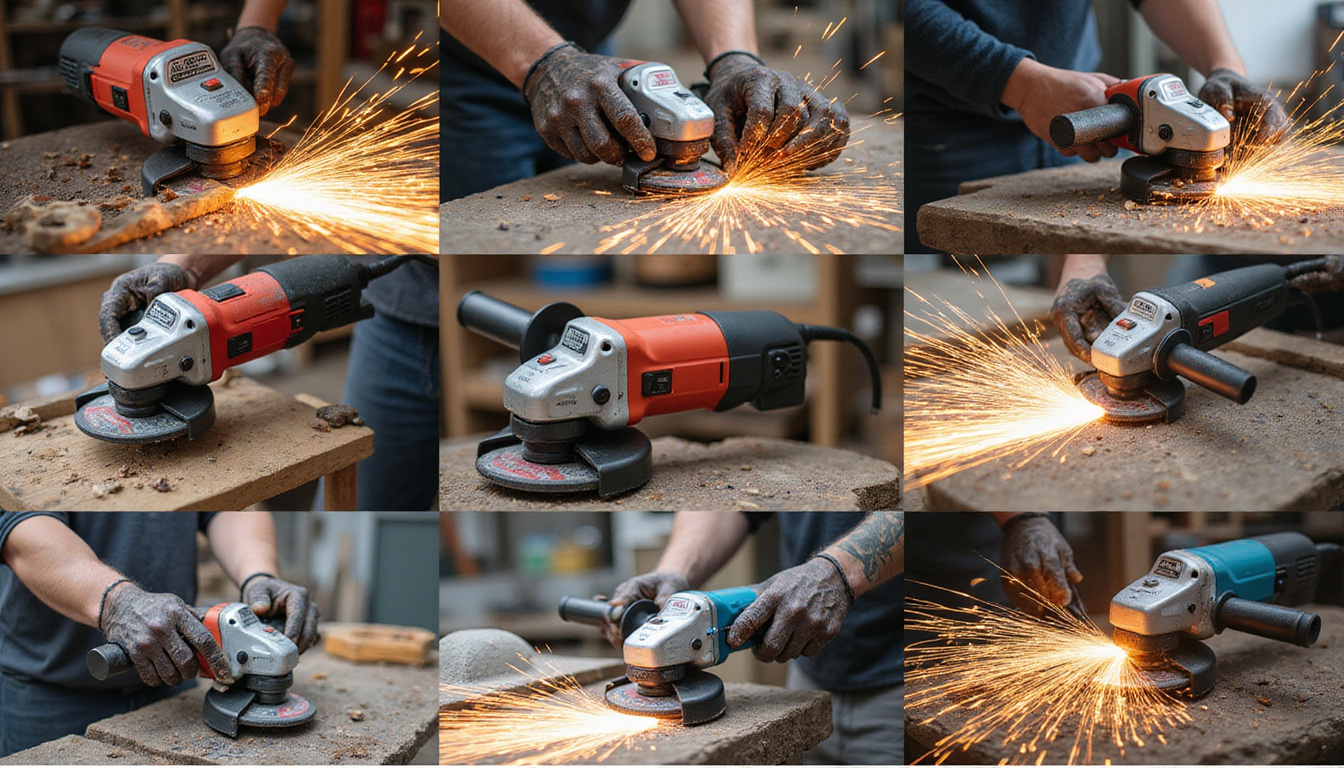

Ever found yourself in a DIY project, contemplating the best tool to achieve that perfect finish? Well, let me introduce you to an unsung hero of the toolbox: the angle grinder. This powerful tool is not just for professionals; it can elevate your DIY game by tackling a wide range of tasks with ease. From cutting and grinding to polishing and sanding, angle grinders are incredibly versatile. In this blog, we'll explore everything you need to know about angle grinders—how they work, essential safety tips, top applications for your projects, and how to choose the right one for your needs. Get ready to unlock the full potential of this fantastic tool!

Key Takeaways

- Angle grinders are versatile tools essential for various DIY tasks.

- Safety is paramount; always wear protective gear when operating angle grinders.

- Angle grinders can cut, grind, and polish materials effectively, enhancing project outcomes.

- Choosing the right angle grinder involves considering size, power, and intended use.

- Regular maintenance is key to prolonging the life and efficiency of your angle grinder.

Introduction to Angle Grinders: What They Are and How They Work

Ever found yourself staring at a project, wondering how to tackle that tough material? An angle grinder might just be the tool you didn’t know you needed! This versatile power tool is a go-to for both professionals and DIY enthusiasts alike. An angle grinder uses a rotating disc to cut, grind, or polish materials, making it indispensable for metalworking, masonry, and even woodworking tasks. Whether you’re looking to smooth out rough edges or cut through thick surfaces, understanding how angle grinders work can make a significant difference in your projects. Let’s dive into the mechanisms behind this powerful tool and discover how it can elevate your craftsmanship!

Essential Safety Tips for Using Angle Grinders

Using an angle grinder can be an incredibly useful skill for both professionals and DIY enthusiasts, but safety should always be your top priority. First and foremost, always wear appropriate personal protective equipment (PPE), including safety goggles to protect your eyes from flying debris, gloves to shield your hands, and a dust mask to avoid inhalation of harmful particles. Ensure your workspace is clear of any flammable materials, as angle grinders generate sparks that can ignite nearby combustibles. Additionally, always check your tool before use; ensure the grinder's guard is in place and functioning correctly, and that the wheel is properly tightened. Never bypass safety features, and be sure to maintain a firm grip on the tool, keeping both hands on it during operation. Following these essential safety tips not only helps you work more efficiently but significantly reduces the risk of accidents.

'The only limit to our realization of tomorrow will be our doubts of today.' - Franklin D. Roosevelt

Top Uses of Angle Grinders in DIY Projects

When it comes to tackling DIY projects around the house, an angle grinder is an invaluable tool in any enthusiast's toolkit. Its versatility allows you to cut, grind, and polish a variety of materials, making it essential for both beginners and seasoned pros. Here are some of the top uses of an angle grinder that can elevate your DIY game:

1. Cutting Metal: Whether you’re working on a metal fabrication project or need to trim metal sheets, an angle grinder with a cutting disc can slice through steel and aluminum with ease.

2. Grinding and Sharpening: From smoothing rough edges on metal pieces to sharpening garden tools, an angle grinder equipped with a grinding wheel allows for quick and efficient material removal.

3. Removing Rust: Tired of unsightly rust on metal surfaces? Attach a wire brush or flap disc to your angle grinder and watch as the rust is quickly eliminated, restoring your metal objects to their former glory.

4. Polishing Surfaces: For those seeking a high-shine finish on metals or even concrete, angle grinders can be equipped with polishing pads, providing you with a professional-looking result without the need for expensive equipment.

5. Cutting Tiles: Embarking on a tiling project? Use an angle grinder to make precise cuts in ceramic or porcelain tiles, ensuring a clean finish around edges and corners.

When using an angle grinder, always prioritize safety by wearing appropriate protective gear. With its wide range of applications, an angle grinder proves to be a powerful ally in achieving your DIY project goals.

Expert Tips for Choosing the Right Angle Grinder

When selecting the perfect angle grinder for your needs, several key factors come into play. First, consider the size and power of the grinder. For most DIY enthusiasts, a

4.5-inch grinder is a versatile choice, ideal for cutting, grinding, and polishing without being too unwieldy. Next, look at the wattage; a higher wattage means more power, which is crucial for demanding tasks. Additionally, think about the type of disc you’ll need depending on your projects – whether you’re cutting metal, masonry, or working with wood. Safety features are also vital; choose a grinder that includes a safety guard and a lock-off switch to prevent accidental start-ups. Don't forget to factor in weight and ergonomics for comfort during extended use. Finally, invest in reputable brands known for quality and durability, ensuring that your tool not only performs well but lasts through numerous projects.

Maintenance Best Practices for Angle Grinders

Angle grinders are indispensable tools for both professionals and DIY enthusiasts alike, but their performance hinges on proper maintenance. To keep your angle grinder operating smoothly and ensure longevity, follow these essential best practices. First, always inspect the tool for any physical damage before use; check the power cord and plug for frays or breaks. Regularly clean the grinder after each use to remove dust, debris, and metal particles that can lead to overheating. It’s crucial to replace worn or damaged grinding discs; not only can they impact the tool's effectiveness, but they also pose a safety risk. Every few months, lubricate the bearings and other moving parts to minimize friction, which prolongs the tool's life. Finally, store your angle grinder in a dry, protected space when not in use to prevent rust and damage. By investing time in maintenance, you’ll ensure your angle grinder continues to perform at its best, cutting through materials with precision and ease.

Frequently Asked Questions

What is an angle grinder used for?

An angle grinder is a versatile power tool used for cutting, grinding, polishing, and finishing materials such as metal, stone, and concrete. It's widely used in various DIY projects and workshops.

What safety precautions should I take when using an angle grinder?

Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and hearing protection. Ensure you're working in a well-ventilated area and keep a firm grip on the grinder to maintain control.

How do I choose the right angle grinder for my needs?

Consider factors such as the size of the grinder (typically 4.5 or 9 inches), motor power, and features like variable speed settings. Choose based on the specific tasks you intend to perform and the materials you'll be working with.

What are some common DIY projects that benefit from using an angle grinder?

Angle grinders are commonly used for metal fabrication, tile cutting, masonry work, and surface preparation. They can also be used for sharpening blades and tools.

How should I maintain my angle grinder to ensure its longevity?

Regularly check and replace worn discs, keep the tool clean, ensure vents are free from dust and debris, and lubricate moving parts as needed. Always refer to the manufacturer's guidelines for specific maintenance recommendations.